From Farm to French Fries

Cooking Up the Future of Fast Food

“Can I get fresh fries?” is the question I get most often working the drive thru at my hamburger restaurant.

Maybe you’ve heard of the “trick” where you ask for no salt on the fries to ensure they are made fresh (we hate that by the way, unless you really need to reduce your sodium, don’t do that). You can also ask for them to be “well done” which in a modern hamburger restaurant is also something we hate, because anything non-standard is slower, and we’re trying to make you a great meal as fast and consistently as possible.

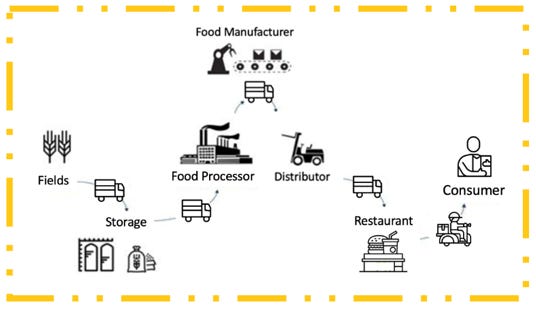

The real question of fresh fries is not just how long have they been sitting under the heat lamp but how long were they in the freezer before that. Who brought them to the store? How long did that take? Who cut them into “fry shape?” At some point these were living potatoes being grown in the dirt... Where was that? Idaho? Somewhere closer? Are they even from the same country?

You have a smartphone in hand and now you’ve got more on your mind than the freshness of the fries. Staring up at the menu, you’re curious about where all of this neatly packaged food comes from. How was it handles? What kind of environmental impact has it has along the supply chain?

You might want assurance that the premium grass-fed beef really is grass-fed. Other times you could be concerned about that recent E. coli headline and want to know if it is safe to order onions. Maybe you’re someone who cares about sustainability so you pay attention to carbon footprints and responsible sourcing. Maybe it’s labor issues, or animal welfare, or just the curiosity that hits while you’re waiting for your order.

The giant nationwide chains address these concerns with pamphlets, social media posts, and vague initiatives about farmers, fair trade, and their charity work. It’s amazing how hard they can work for information that is nearly impossible to find and definitely impossible to verify. I’m sorry, but I just have a hard time believing any company that is selling me on how “good” they are when they present it on glossy paper designed by their PR machine.

Because this shouldn’t be just a feel good marketing ploy. Transparency matters!

In November of 2024, McDonald’s suffered an E. coli outbreak traced back to tainted onions. Because it wasn’t immediately clear which onion batch caused the crisis it led to restaurant closures, destroyed inventory, millions in lost revenue, and a generalized customer panic. Public trust dipped noticeably, and the brand’s reputation (and stock price) took a hit that’s still being repaired. Incidents like this highlight just how crucial it is to know precisely where your ingredients come from—and that restaurants should be proactively transparent about that information with customers.

Welcome to Fast Food 2.0, where brand trust is the main course. It’s not enough to have the best supply chain providing the freshest high quality ingredients, you have to be able to prove it. Here are three big reasons why supply chain transparency is a super-sized deal:

Supply Chain Verification (Grass-Fed? Prove it.)

Think of this like a DNA test for your beef. If the suppliers say it’s grass-fed, they better have the data to back it up, and the restaurant better have insights into that data because yes, your customers want to see the proof! More on that in a moment.Safety Recalls (Data driven crisis management)

It’s not a matter of “if” but when… if you’re not prepared for when a microscopic troublemaker sneaks in (hello, E. coli!) you shouldn’t be in this business. You have to track it and shut it down—fast. Targeted recalls help you avoid the “recall everything on the west coast” approach and zero in on the problem locations, calming everyone’s contamination fears as fast as possible.Granular Environmental Impact (Counting Every CO₂ Molecule)

More and more folks want to see just how green—or not—your supply chain is. Did those avocados travel in a private jet? Or is your entire distribution network feeling more green than a Whole Earth meetup in the 1970s? How can you be sure and how can you share your confidence with the customer?

Of course, all this is easier said than done. How many companies can accurately track the source of their ingredients from the source all the way to the individual restaurant? The cost of implementing a supply chain tracking system like this could be wildly expensive and create a dependence on the software and vendors that trap a company into a logistics nightmare. Maybe it’s easy for the big transnational chains because with their franchise fees across thousands of locations can absorb the costs. Maybe the smaller chains, suppliers, and individual operators are out of luck.

Or…

Maybe there is an advantage to being a little smaller than the big boys. Maybe being small means you are more nimble and adaptable, and that means you can evolve and leave the giant dinosaurs behind.

I can tell you that as a fan of the regional chain, a burger joint with a few locations across the city, or even just the single local favorite, I want you to compete with the dinosaurs and I want you to win. There are any number of vendors and software solutions for POS systems, online ordering solutions, guest data platforms, and the push to digitize the guest experience.

A Local-First Database

It’s essential to start with the right database choice. Because if you apply best in class new technologies, projects like these become more achievable.

A great example is Fireproof, a new local-first database that runs on your personal device, in addition to in the cloud. Because it automatically syncs a dataset across multiple users it makes supply chain deployments far more hardy and accessible than cloud applications.

Now, let’s roll up our sleeves, wash our hands (twice), and take a look at how using something like Fireproof’s local-first database technology could empower a new era of supply chain transparency.

Part 1: Building a Transparent Chain of Custody with Fireproof

Why Unit-Level Serialization is Critical

Transparency goes hand-in-hand with being able to track every item from its earliest origin point—like a head of lettuce grown in a local field—to its final destiny on a customer’s tray.

Let’s talk about a cutting edge evolution of modern supply chain management: unit-level inventory tracking (sometimes called “unit-level serialization”). Instead of lumping everything into one giant batch, you give each item—or smaller batch—its own unique, trackable identity. Think of it like handing every head of lettuce or box of patties its own digital ID card.

I know exactly how these systems work – Marcus (S2E7 guest) and I founded a company that built a barcode serialization platform for the cannabis industry. It was acquired by the largest cannabis “track and trace” vendor in the world. These serialization systems not only trace each product’s journey from its earliest origin point—a family-owned farm or a major distribution center—all the way to the customer’s tray, but also ensure you can zero in on exactly which items need attention if something ever goes wrong. It’s a next-level approach that top-tier brands rely on to deliver transparency, cut costs, and keep customers’ trust firmly in place.

That’s why unit-level serialization is so crucial. It makes it much easier to zero in on a specific problem if a safety issue arises. Instead of recalling everything that might possibly be tainted, you can isolate the exact shipments (or even individual items) that need to be removed from circulation.

On a larger scale, this tactic helps reduce waste, control costs, and maintain consistency in a business where minutes and margins count. Other industries have already mastered this practice.

Pharmaceuticals, for example, are heavily regulated and require precise traceability to ensure patient safety.

Electronics manufacturers assign unique serial codes to every component to allow for swift recalls and warranty verifications.

Luxury goods companies safeguard authenticity by embedding digital certificates or microchips in their high-end handbags and accessories.

Following these examples, fast food operators can bring the same level of granular oversight to their own supply chains, building not just efficiency and quality control but also a reputation for reliability.

You could argue that every supply chain will serialize itself once the benefits of doing so exceed the costs of implementation. Fireproof slashes the costs of serialization so drastically that we think every consumer supply chain should investigate. Here’s how it works.

The Key to Serialization: Unique Identifiers

Assigning each product a Unique Identifier (UID) is step one. That might be as simple as “ingredient:random-hash-of-letters.” Store it alongside fun facts like origin, temperature logs, and the cow’s life goals. Then, keep it all in a database that’s designed to handle it gracefully.

At the heart of serialization is the simple act of creating a unique identifier and storing the relevant data—such as origin and environmental conditions—right alongside it. Generating and storing one of those “digital ID cards” using Fireproof, a ledger-based local-first database, is easy. Fireproof’s sync connection ensures you have a permanent record of the item’s attributes complete with timestamps and tamper-evident proofs.

The Challenges of Serialization

Of course, no approach is without its challenges. One tomato is easy. A million tomatoes is a circus, especially when you need to track them all.

Moving from batch-level tracking to true unit-level serialization can dramatically increase the volume of data you manage. Ensuring that each record remains accurate and free from tampering becomes a top priority.

No wifi? No problem!

Many distributors or suppliers might operate with limited or unreliable connectivity, so any truly functional system must work offline and sync seamlessly when back online. Smaller-scale vendors also need a user-friendly way to adopt these technologies, otherwise you risk a patchwork of partial compliance. And inevitably, you’ll run into regulatory variations from one region to another—what satisfies the rules in one market may only be half of what’s needed elsewhere.

Fireproof addresses these obstacles by embracing a local-first architecture and lightweight footprint with immutable ledger consistency.

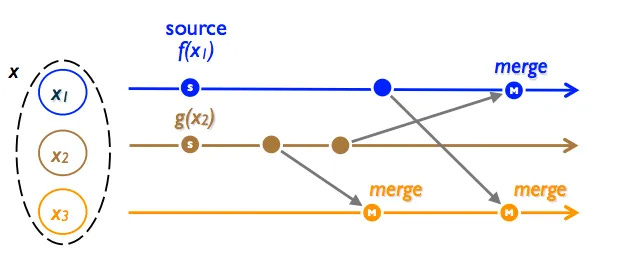

Because each device can run Fireproof locally, it’s easy to capture and store data—like a scan of incoming shipments—even if the store’s or truck’s connection is down. As soon as the device reconnects, Fireproof merges all changes, thanks to its conflict-free replicated data types (CRDTs).

CRDTs ensure that when multiple people update the same record, the final version remains consistent, clear, and complete.

Consistent compliance

Fireproof leverages Merkle proofs to create a cryptographic chain of evidence around every data entry, so if someone tries to alter a record—or conceal a recall—you’ll be able to detect it right away. No more counterfeits! You know what you’re running because it’s open source; you can slap it on a smartphone or a dusty old tablet, and you’re good to go—no NASA-level supercomputer required.

And this cryptographically verified ledger opens up a new superpower: multiple organizations can collaborate on a single dataset, even when regulatory scrutiny demands total oversight. This means you can do verified supply chain transactions that get signed by multiple parties, and present a single verified view of the data to consumers and regulators alike.

Part 2: Consumer Transparency & the Fireproof-Powered BYOD Point of Sale

Verifying the Supply Chain at the Point of Sale (POS)

Now comes the magic trick: letting your customers see their food’s “origin story” in real time. Here’s how it works:

QR Code Scanning: Print a QR code on the receipt. Your customer zaps it with their phone camera.

Local-First Query: The phone has a mini Fireproof database that either has the data cached or pulls a quick sync from the store’s system. No “spinning wheel of death” if the network is throwing a tantrum.

CRDT & Merkle Proofs: Under the hood, Fireproof is checking cryptographic receipts (Merkle proofs) to confirm everything’s legit. If your supply chain data was messed with, the system would cry foul—loudly.

But why wait until the customer has already made their order? Fireproof can also help move the entire point of sale transaction to the customer’s mobile device.

Order Anywhere

A consumer Bring Your Own Device (BYOD) POS system empowers customers to use their personal smartphones or tablets to place orders, make payments, and even interact with loyalty programs while dining at a fast food restaurant. Below is an overview of the key advantages this approach can deliver:

Faster and More Convenient Ordering

Starbucks, McDonald’s, and every other major high-volume player has gone all in on direct ordering apps. When customers can pull out their own phones to view menus, customize orders, and pay, they effectively skip the line at the counter. This leads to shorter wait times for everyone. Guests can order exactly what they want without feeling rushed, making the ordering process more relaxed and efficient.Reduced Labor and Operational Overhead

A consumer BYOD system means fewer staff members need to be dedicated to taking orders at physical terminals. Employees can instead focus on food preparation, customer service, or housekeeping tasks which help the restaurant run more smoothly. Eliminating the need to staff a register also cuts down on potential human errors in data entry.Seamless Loyalty and Rewards Integration

A direct order solution also streamlines loyalty program signups and redemptions. Customers can log in to their existing loyalty accounts or sign up on the spot, then instantly see or apply reward points, coupons, or special discounts during checkout. This eliminates the need for separate loyalty cards or complicated processes, making it more likely that guests will participate in your rewards program.

The Future of the Burger

In this brave new fast food world, transparency is a sizzling competitive edge. By tagging each patty, verifying its origins with cryptographic flair, and letting diners see every detail on their smartphones, you’re turning an average burger run into a trust-building exercise. From verifying grass-fed claims to zapping E. coli surprises and cutting carbon footprints, a Fireproof-powered supply chain and point-of-sale solution keeps everyone happy, informed, and maybe just a bit impressed.

So go on, dazzle your guests with real-time data and unbeatable uptime. After all, who doesn’t love a burger that comes with a side of peace of mind?